CNC Turning

CNC Turning Services

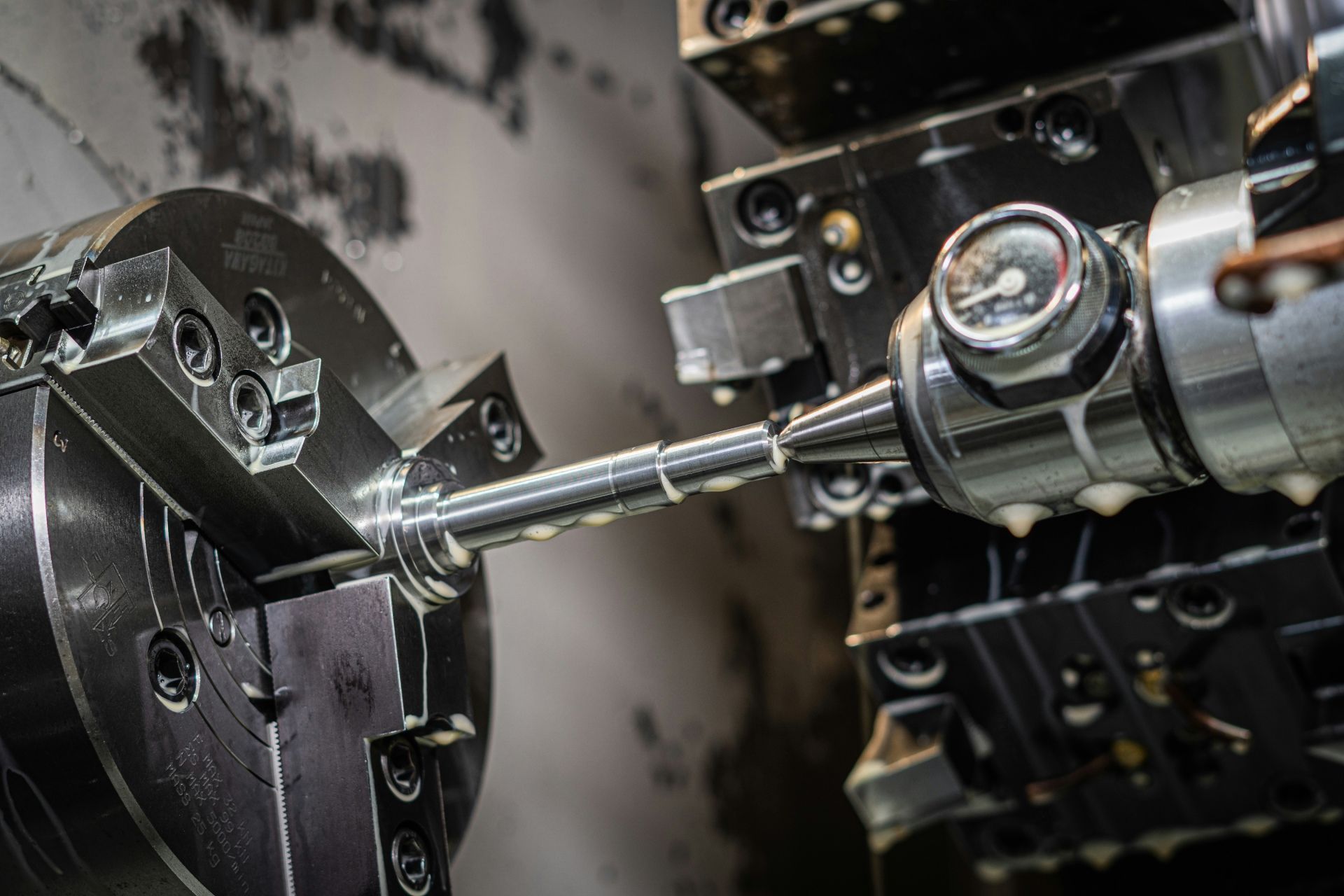

Do you want to create parts and components for your company that are as precise as possible? Since 1976, the experienced technicians at Custom Machine, INC. have been utilizing a process called CNC turning to take the blueprints for parts and bring them to life. Whether you’re interested in creating a one-piece prototype or a full production run for a specific part, we have the tools and expertise to get it done.

With the CNC machining services from Custom Machine, INC., you can create metal or plastic pieces that are custom built to meet your needs. Unlike machining done with a traditional lathe, CNC turning allows us to use multiple cutting actions at once, which results in more precise parts and components. We manufacture quality parts that meet industry standards. The parts will also feature a superior finish, and maybe best of all, it won’t take us long at all to fulfill your order and send it to you when we use CNC turning.

At Custom Machine, INC., we have clients from across the country who have turned to us time and time again for their CNC machining needs. They appreciate the precision that goes into each and every part we make, and they know they’ll be able to get access to their parts quickly when they trust us to make them.

Contact Custom Machine, INC. at (815) 284-3820 today to see how CNC turning can benefit you and your business.

Get advanced turning

- Metal

- Plastic

- Multiple cutting actions

- Boring

- Tubular components

- Various shapes

Application Benefits

Rapid Tooling

Because CNC can be applied to virtually any material, it is perfect for rapid tooling, i.e., creating fixtures or molds.

Serial Production

High-quality finish, vast material options, and precise tolerances have made CNC lathe turning a favorable technology for serial production parts.

Rapid Prototyping

The range of materials available, low cost per unit, and speed of production makes CNC a great option for prototyping.

CNC Turning Materials

Here are the materials we use at Custom Machine Inc.

| Material | Available Varieties |

|---|---|

| Aluminum | Aluminum 5052, Aluminum 7075, Aluminum 7075-T6, Aluminum 6063-T5, Aluminum 7050-T7451, Aluminum MIC-6, Aluminum 6061-T6, Aluminum 2024-T3 |

| Brass/Bronze | Brass C360, Brass 260, C932 M07 Bearing Bronze |

| Plastics | ABS, Acetal [Delrin], Acrylic, G-10 Garolite, Nylon 6/6, PEEK, Polycarbonate, PTFE [Teflon], Polypropylene, Ultra-High Molecular Weight, Polyethylene |

| Steel | Alloy Steel 4130, Alloy Steel 4140, ASTM A36, Stainless Steel 15-5, Stainless Steel 18-8, Stainless Steel 303, Stainless Steel 304, Stainless Steel 316/316L, Stainless Steel 416, Stainless Steel 420, Steel 1018, Steel A36, Steel 1045, 1144, 12L14, Fatigue Proof, Stress Proof |

Finishes

| Available Finishes | Description |

|---|---|

| As-Milled | The finish option with the quickest turnaround. Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. Surface finish is comparable to 125 uin Ra finish. |

| Bead Blast | The part surface is left with a smooth, matte appearance. |

| Anodized (Type II Or Type III) | Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and is usually associated with aluminum.Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II. |

| Powder Coat | This is a process where powdered paint is sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic. |

| Custom | Don’t see the finish you need? Submit a request and we’ll look into a finishing process for you. |

CNC Turning Tolerances

| Description | General Tolerance |

|---|---|

| Distance Dimensions | For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) +/- 0.005”. |

| Orientation and Form Dimensions | 0-12" +/- 0.005", Angularity 1/2 degree. For 24" and beyond please consult us. |

| Edge Condition | Sharp edges will be broken and deburred by default. Critical edges that must be left sharp should be noted and specified on a print. |